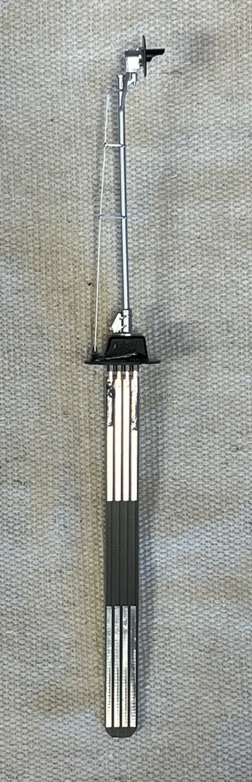

1. The parts of the PCB Stick

The PCB Stick has three parts. The stick, a double row header,

and a disc that the signal mounts to.

|

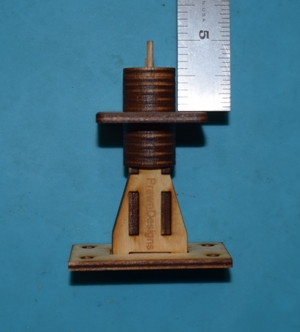

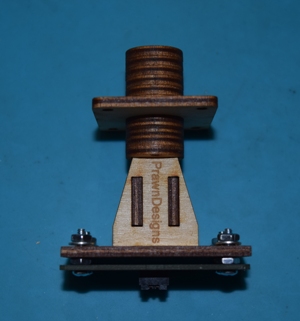

2. The PCB Stick Assembled

This is what the assembles PCB Stick looks like.

|

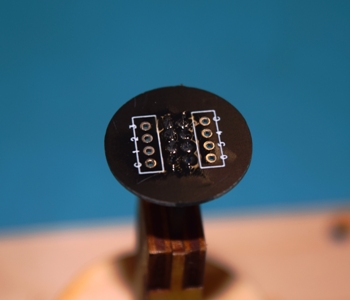

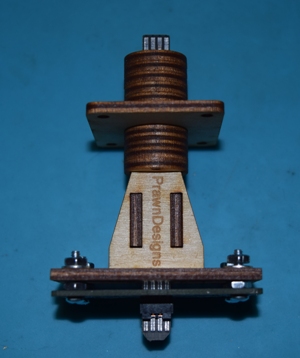

3. Top of the PCB Stick

The top of the PCB Stick is a 3/4" round disc that the signal

is mounted to. We recommend some kind of glue like 5 minute

epoxy. There are 8 solder pads for 4 wire from each head. The

fine wires are kept between the round disc and the bottom of

the signal, protected from getting snagged.

NOTE: This disc us upside down, ERROR

|

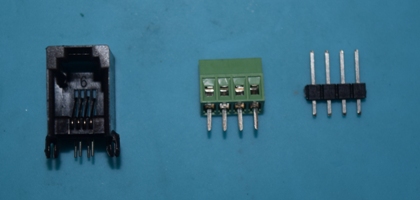

4. Connection Options

There are three connector options for connecting your signal

driver to the Signal Mount. First there is a Modular 4P4C Jack

(J3 and J4) for plug and play ease using a Big Ditch Designs

Signal Driver. We included a 0.10" (2.54mm) spaced set of solder

pads to take a pin header or a screw terminal. A fourth option

would be to solder wires right to the board on the pads.

|

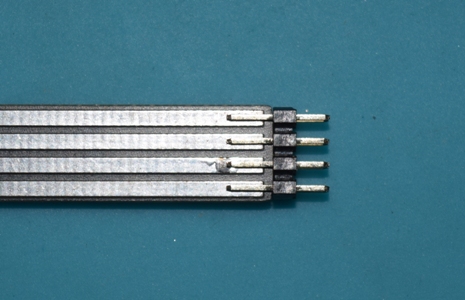

5. PCB Stick Assembly Step 1

Place the double row header on the top of the PCB Stick.

The long pins onto the stick is preferred but not required.

Solder both sides.

|

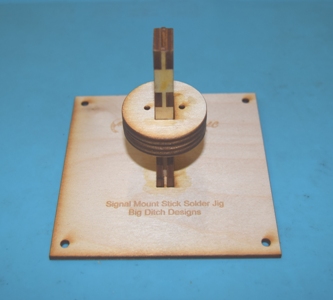

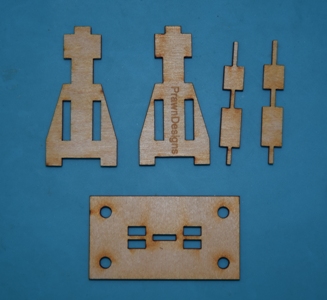

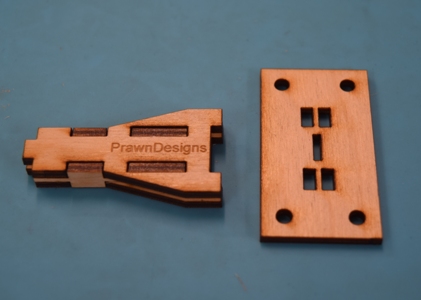

6. PCB Stick Solder Jig

We make a soldering jig to help hold the PCB stick while

soldering the parts onto it. The double row header it stays

in the stick and it not bad. But the next step is to solder

the PCB disc onto the top of the stick. Placing the stick in

the jig makes it easy to keep the PCB disc square to the stick.

If the round is not square to the disc, your signal will lean.

|

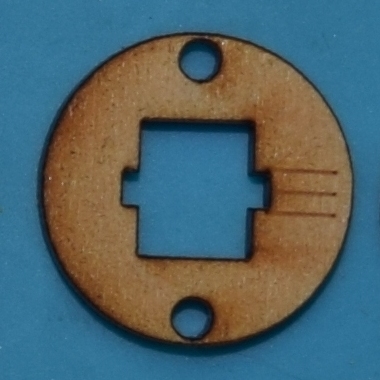

7. PCB Disc Placement

One side of the PCB Disc has one square on it, the other

side has two squares on it. The side with the one squares goes

up. See the image below. Place the stick in the jig, place the

PCB Disc on top of it. Be sure the disc is level and solder

in place.

You can use the jig to hold the assembled stick while you

solder the signal wires onto the stick. Then glue the signal

onto the stick, watching to be sure the signal is vertical.

NOTE: This disc is upside down.

|

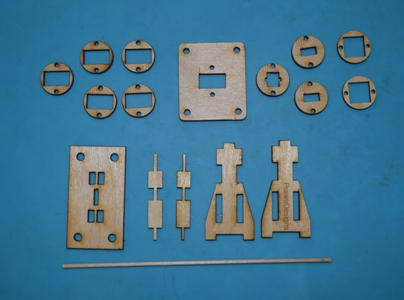

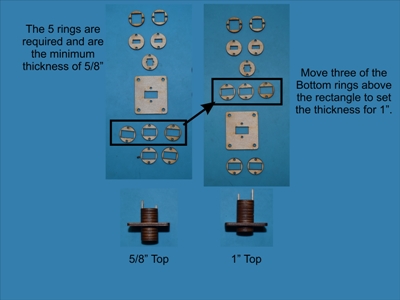

8. Laser Cut Base Parts

On the top are the laser cut rings, the bottom are the base

pieces. There is also a small dowel included.

|

9. Main Bass Assembly

Gather the 5 main base pieces.

Do not use any glue yet, place the two smaller spacer piece

into one of the sides.

Place the second side onto the assembly.

Place the side assembly onto the bottom.

It is very important that you do not get any glue in the

center slot formed by the sides and spacers. I do not put any

glue on these pieces. I put a small amount on the bottom before

I place the sides assembly onto it.

I use a q-tip to mop glue around the base.

Again it is very important to not get any glue in the center

slot.

Let the assembly dry.

|

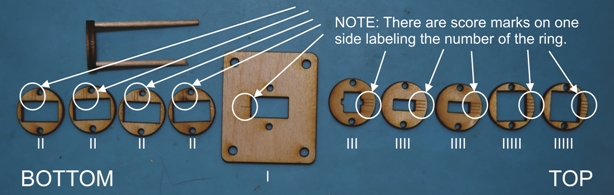

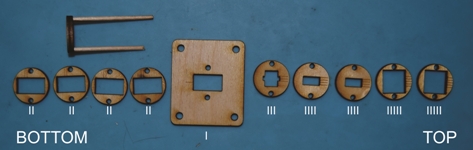

10. Base Rings

There are 10 round rings and one square ring. By changing

the order of the rings the mount can be adjusted in 1/8" (really

closer to 0.12") steps to accommodate different thickness of

module tops (bench work). The system is adjustable between 5/8"

and 1 1/4". When measuring your bench work thickness remember

to include the thickness of your scenery material where the

signal will be mounted.

Note: Two of the rings (2 and 5) are a little fragile and

sometimes break, so I include some spares rings, not shown in

the image.

Ring Markings

The rings are not all the same. The rings are marked (numbered)

on one side with small score marks (lines). These indidate which

ring is which. The top five rings IIIII, IIIII, IIII, IIII,

III are required. They must be in the correct order to have

room for the top of the stick to fit into the base. Rings marked

II can go above or below the large square ring marked I. This

is to adjust for the thickness of your benchwork.

Ring Assembly

You can do a dry fit without glue to check the height of

the stack to your bench work, the fit on the dowel is very snug.

Be careful, you can break the rings putting them together and

taking them apart.

In this example I am assembling a mount for module top (bench

work, sub-roadbed) that is 5/8" thick. This measurement is the

distance from the of the module top to where you want the base

of the signal to sit including scenery material.

Take the small dowel and cut two pieces about 2" long. Stack

the discs, in order, onto the two dowels placing a small amount

of glue between each disc. From top to bottom the discs go in

this order.

IIIII, IIIII, IIII, IIII, III, I, II, II, II, II, II

(two 5, two, 4, one 3, one 1, five 2)

NOTE: the image below only shows four number 2 rigns, but

5 are used, plus one extra 5 and 2 ring.

After the first set of discs put the rectangle on. This is

the mounting plate, it will be screwed to the bottom of you

sub-roadbed.

In order place the rest of the rings onto the dowels.

NOTE: The arangment shown is for 5/8" thick bench work, sub-roadbed,

if you need it thicker, move the number 2 rings up to between

the Number 1 (rectangle) and number 3 ring one at a time to

get the desired depth up to 1 1/4" |

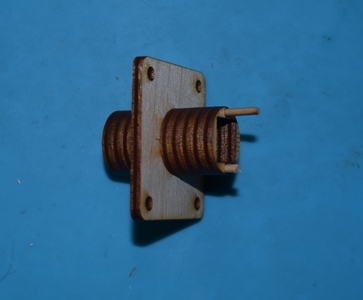

11. Put the Rings on the Base

This stack is now placed onto the base. I use a q-tip to

mop glue onto the sides of the base and slip the rings down

on. Be sure to seat the rings all the way down onto the base.

The first of the top rings keys down onto the base, look down

into the top to ensure it is seated all the way down.

In this example I made the shortest mounting base possible

with only the 5 required rings on the top. You can see that

the 5 required rings make a mount for 5/8" thick sub-roadbed.

This measurement includes any scenery (dirt, ballast, etc.)

that will be under the signal base.

When the glue dries use a knife to trim the dowels flush.

|

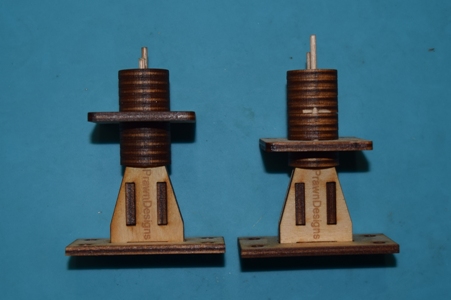

12. Thicker Bench work / Taller Mount

To make a mount that is taller, move one or more of the rings

from the bottom to the top of the rectangle piece.

The one on the left is setup for 5/8" the one on the right

is setup for 1".

|

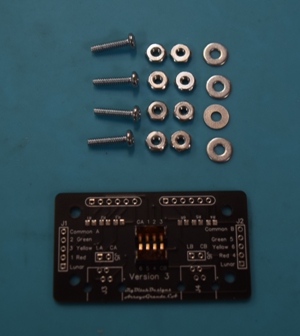

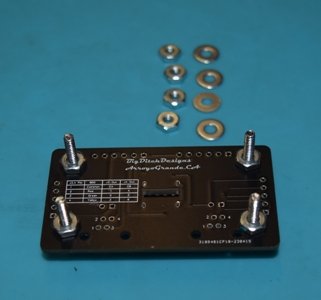

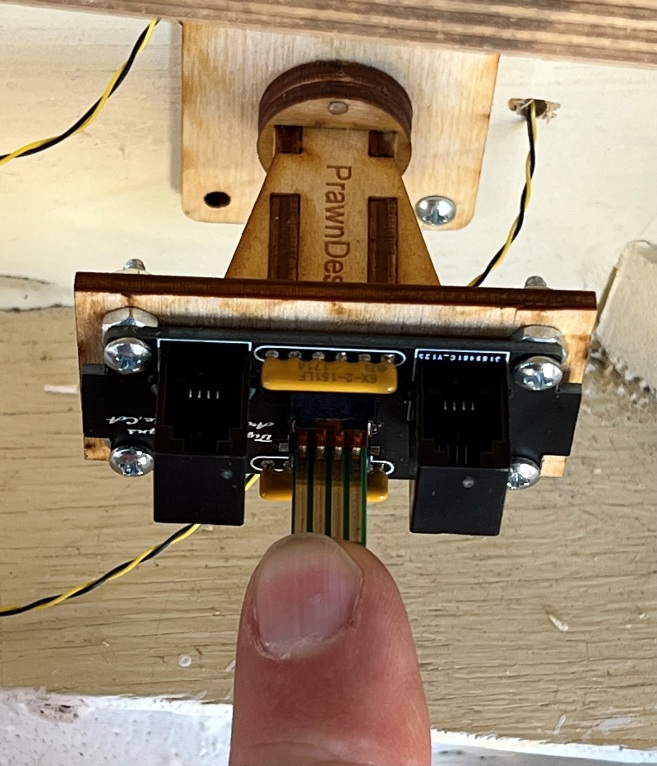

13. Mounting the Bottom PCB

You should have soldered in your resisters and connectors

(Modular 4P4C, pin header, or a screw terminal) you choose to

use. The picture below does not have the connectors or resisters

installed on the Bottom PCB

The part you will need are:

The Bottom PCB (with resisters and connectors soldered on)

(4) #4-40 1/2" Machine Screws

(4) #4 washers

(8) #4-40 nuts

|

14. Install Machine Screws

Install the 4 machine screws from the side with the components

and put a nut on the back of each screw. Tighten the nuts down

snug.

|

15. Mount PCB on Base Assembly

Place the Bottom PCB onto the Main Base assembly and place

one washer and one nut on each or the mounting machine screws,

do not tighten these yet, leave them loose.

Note, there will be some play this will allow the Bottom

PCB to move around a little.

|

16. Align and Tighten the Bottom PCB

Place a PCB Stick into the Main Base assembly from the top.

Use it to align the Bottom BCB, then tighten the nuts. You should

be able to remove and insert the PCB Stick with just a little

force. Loosen, realign, and tighten the nuts if needed.

|

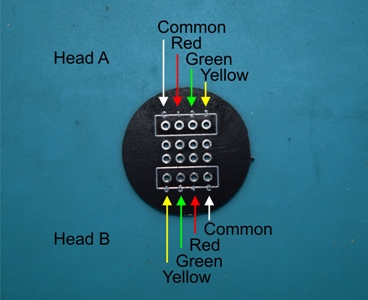

17. Connecting Your Signal

At this point you should have:

- The Main Base assembled for your thickness of bench

work where you will be installing the signal.

- Your resisters installed on the Bottom PCB

- Your choice of connectors installed on the Bottom PCB

- The Bottom PCB aligned and installed on the Main Base

- The PCB Stick, double row header, and PDB Disc soldered

together.

Time to connect your signal to the PCB Disc on the PCB Stick.

Solder the signal wires from your signal head to the corresponding

solder pads on the PDB Disc.

|

18. Test and Glue Signal to PCB Stick

You should test your signal head before gluing your signal

to the PCB Disc.

This system is designed to have the flat side of the PCB

Stick facing the track, see the image below.

After you have tested your signal, tuck the extra wire up

into the base and glue the signal base onto the PCB Disc.

Signal NOT included.

|

19. Mount the Main Base Assembly

The System requires a 3/4" hole in your bench work. Bring

the Assembly up from the bottom and screw it into place. Ensure

that the PCB stick is aligned correctly.

|

20. Removing a Signal

Place your signal on the PCB stick into the mount and press

down gently on the PDB Disc to set it into the base. To remove

the signal, press up in the bottom of the PCB stick to lift

the signal slightly out the layout. Then lift the Signal out

by the PCB Disc.

|